|

|

Post by Mark Stubbs (DeCav) on Sept 7, 2015 23:29:52 GMT -4

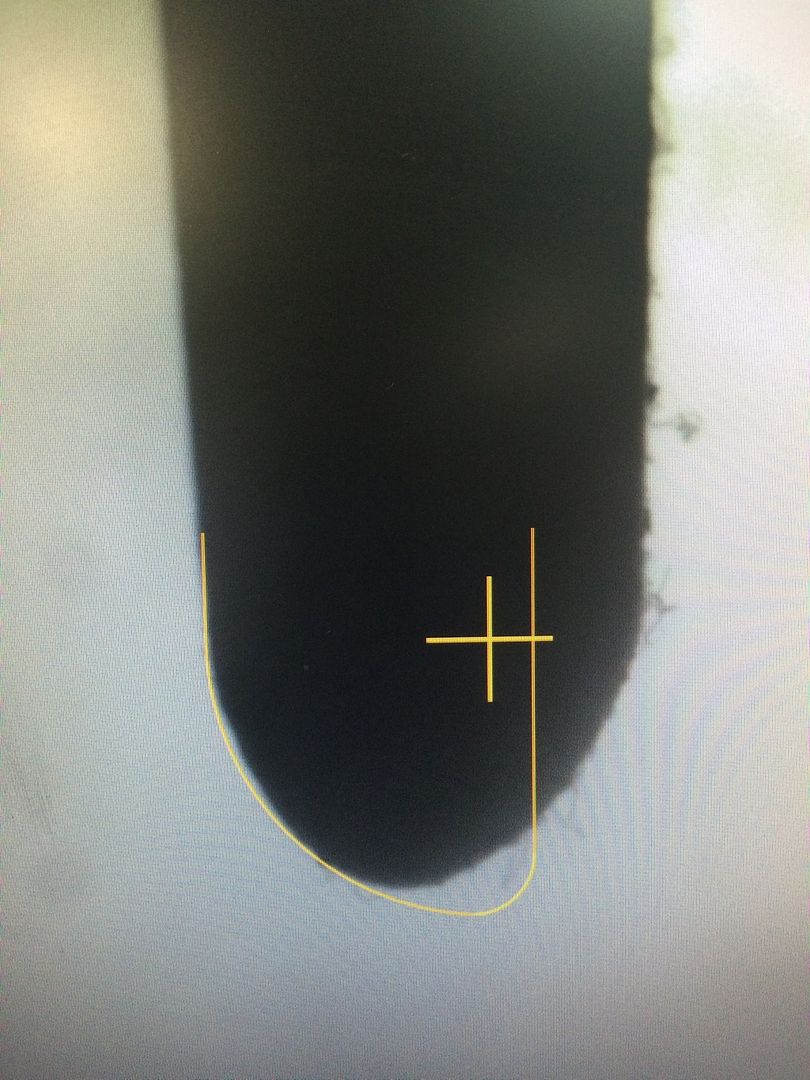

CF35101- Oil Hole drill

After the 1st flute wheel flew apart, Tyler and Phil have a new wheel dressed, mounted and dry run. I'm gonna see if I can get this last little bit of tools left off the machine without anymore problems.

|

|

|

|

Post by Mark Stubbs (DeCav) on Sept 8, 2015 6:26:43 GMT -4

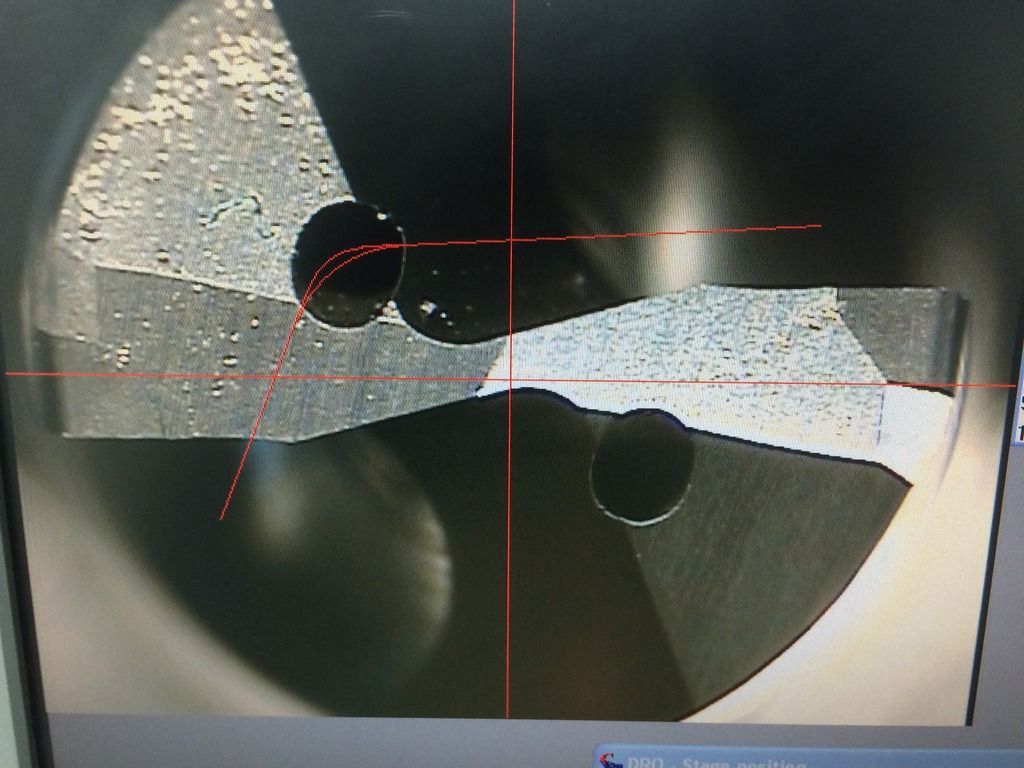

The geometry dressed on the wheel did not match the geometry called out in the software...  This made the lip distance, lip straightness, point angle, relief, chisel angle, all come out whacky...  I made some corrections to the geometry dressed on the wheel and then changed the program to reflect the geometry that was really dressed on the wheel which fixed the problem. |

|

|

|

Post by Mark Stubbs (DeCav) on Sept 8, 2015 6:27:48 GMT -4

Just that one tool which is probably not good because of the flute face concave curvature.

|

|